Hello! I have spent a long time managing my website https://www.hg-machine.com/ . I will keep being active and keep posting updates. If you happen to need my products, welcome!

Let’s face it: even experienced operators can make rookie mistakes with a food machine . Whether it's rushing through a setup or skipping daily checks, small errors can turn into big problems fast.

Here’s how to avoid the most common missteps—and keep your machine (and sanity) running smoothly.

1. Skipping the Manual and “Winging It”

We get it. Manuals are long. Buttons are tempting. But pressing random settings just to “see what happens” is like baking with no recipe—exciting, but risky.

Even just reading the quick-start section can help you avoid jams, overheating, or worse, calling the technician on Day 2.

2. Overloading the Machine Like It’s a Dump Truck

More input doesn’t always mean more output. Stuffing too much mix or material into your food machine will stress motors, clog nozzles, and mess with timing. Use the correct load sizes. Your machine will thank you, and so will your product quality.

3. Ignoring That Weird Noise (Until It Becomes Smoke)

A small squeak or hum today could be a breakdown tomorrow. Don't turn up the music and hope it stops. When your food machine speaks, listen. Call maintenance early—it's faster and cheaper than replacing burnt-out parts. Avoiding these simple mistakes extends the life of your equipment and keeps production smooth. If you're looking for machines that are easier to use (and harder to break), explore options at www.hg-machine.com/product .

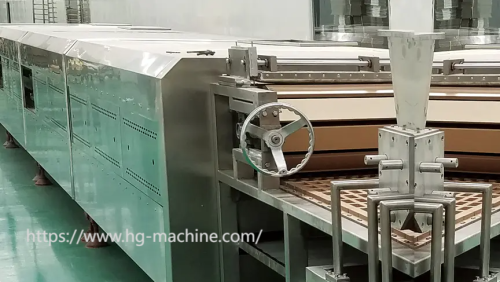

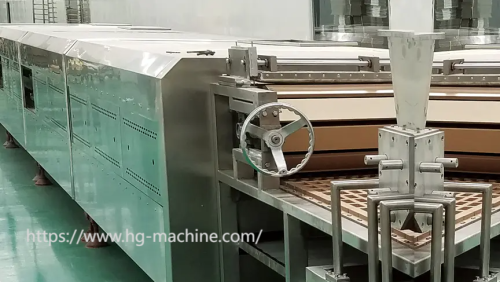

In the food manufacturing sector, achieving both speed and product consistency is a constant challenge. A well-designed food machine can streamline workflow, minimize human error, and deliver uniform quality even at high volumes. Whether producing baked goods, frozen meals, or snacks, precision at each stage of the process is vital for brand reputation and cost efficiency.

Manufacturers aiming to scale operations often face bottlenecks due to outdated equipment or disjointed processes. Upgrading your production line to integrate smart automation, efficient layouts, and responsive control systems can lead to significant performance gains.

Achieving Operational Speed Without Sacrificing Quality

High output is only useful if product quality remains intact. One strategy is integrating automation where timing and measurement are critical. For instance, automated dosing and portioning systems reduce the risk of inconsistency caused by manual operations. Smart conveyors and synchronized systems allow for faster transitions between mixing, forming, and packaging without compromising safety.

Equipment with quick-change capabilities and programmable settings also helps manufacturers switch between products or batch sizes without downtime. This flexibility is especially valuable for businesses with seasonal or custom product lines.

Quality Control and Real-Time Monitoring

Real-time data plays a critical role in optimizing a food production line. Integrated sensors and analytics tools allow operators to track temperature, moisture, and processing time with precision. Alerts can notify staff of deviations before they affect large batches, minimizing waste and ensuring compliance with food safety regulations.

Additionally, consistent cleaning protocols and CIP (Clean-in-Place) systems keep the entire line sanitary and ready for round-the-clock production. Efficiency is not only about speed—it’s about reducing rework, contamination, and operational interruptions.

For reliable solutions that enhance both performance and quality in your food production line, visit https://www.hg-machine.com/ . Their smart machinery is tailored for fast-paced, high-quality food manufacturing.

In today’s fast-paced food industry, efficiency is everything. A high-performing food machine that integrates multiple functions—such as mixing, filling, forming, and packaging—can drastically improve output and reduce labor needs. As production demands rise, multi-function equipment has become a go-to solution for manufacturers seeking to optimize workflows while maintaining consistent product quality.

Streamlining Complex Workflows

One of the most significant advantages of multi-function food machines is their ability to handle several processes within a single line. Traditionally, food preparation involved multiple machines, each performing a specific task. This approach not only required more space but also increased downtime due to manual transfers between steps.

Modern multi-purpose systems eliminate these inefficiencies by combining critical stages. For example, dough can be automatically mixed, shaped, and baked in a continuous flow, reducing waiting periods and minimizing human error. With such automation, businesses can process large volumes without compromising hygiene or consistency.

Moreover, these machines are often equipped with programmable logic controllers (PLCs), allowing for quick recipe changes and process adjustments. This adaptability is ideal for facilities that produce a range of products or seasonal items, making them more responsive to market demands.

Saving Labor and Reducing Operational Costs

Labor shortages and rising wages have pushed many food producers to reconsider how they allocate human resources. Multi-function machines reduce the need for manual labor in repetitive or physically demanding tasks. By automating steps like portioning or sealing, operators can be reassigned to higher-value tasks such as quality control or product development.

This shift not only saves time but also contributes to a safer work environment by minimizing contact with hot surfaces, sharp tools, or high-pressure systems. Additionally, fewer machines mean reduced maintenance schedules, lower energy consumption, and less cleaning time between production cycles.

The investment in an advanced system may seem high initially, but long-term savings in operational costs, waste reduction, and improved speed often deliver a strong return. For small and mid-sized businesses, entry-level multi-function models are available that offer scalability as the operation grows.

Making the Right Choice

When choosing a multi-function machine, it’s important to evaluate your specific production needs. Consider the types of products, production volume, space limitations, and sanitation requirements. Some systems offer modular configurations, allowing for future upgrades without major changes to the production line.

To explore a wide range of high-efficiency equipment designed to support food manufacturers from mixing to packaging, visit https://www.hg-machine.com/. Their machines are built to meet the evolving demands of modern food processing with flexibility and reliability.